For beginners in the hydraulic systems industry, confusion on whether they should use a variable or a fixed displacement pump is common. Selecting the right pump will have a huge effect on your hydraulic system’s performance, operating cost, and operational efficiency. In this post, we discuss the difference between variable and fixed displacement hydraulic pumps.

Purpose of a pump in a hydraulic system

A hydraulic system pressurized fluid to produce the energy that drives the machinery. The hydraulic pump works by drawing the fluid from the reservoir and channeling it down the hydraulic system. Both variable and fixed displacement pumps are positive displacement pumps. Displacement refers to the fluid volume that is moved by the pump for each complete cycle.

Variable displacement pumps

The outlet pressure and flow rate in this kind of pump can be altered while the pump is running. The amount of fluid displaced can be altered by adjusting the speed of operation, repositioning the displacement control, or both

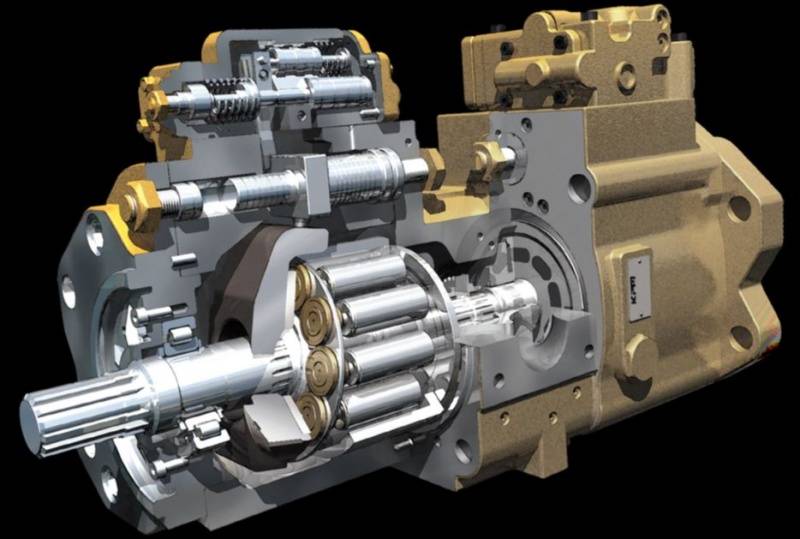

In a displacement pump, the amount of flow depends on the number of rotating pistons. By controlling the pistons’ stroke, you adjust the pump’s displacement. In a variable displacement pump, this is achieved by adjusting the angle of the rotating pistons by tilting the system’s swashplate. Variable displacement pumps are used in vehicles as axial piston pumps. Variable displacement pumps are common in mining, oil and gas, and construction industries. These pumps do not require to be operated manually. Rather, the valves which control the actuators’ speed control the rate of fluid flow. However, they are complex and costlier compared to a fixed displacement pump.

Fixed displacement pumps

In a fixed displacement pump, the amount of displaced fluid can only be changed by adjusting the operational speeds. Fixed displacement pumps are used in open center systems. They are ideal for a wide range of applications where the amount of energy or pressure is constant.

These pumps are simple to operate, easy to maintain, and relatively cheap. The gear pump, screw pump, and the bent axis piston pump are the most common types of fixed displacement pumps. As industrial hydraulic systems normally run on electric motors, applications of fixed displacement pumps in industrial applications are quite limited.

When selecting a pump for your hydraulic system, you will need to answer such questions as:

- What application are you using it for?

- What amount of energy or force will be required to run the system efficiently?

- What are the operational requirements?

- What type of actuators will you use?

Answering such questions will help you establish whether your system requires a variable or a fixed displacement pump. Our experts will also guide you on what’s suitable for your system’s requirements. Contact us at +44 (0) 1475 742500.