An industrial winch is basically a device that is used to pull heavy loads horizontally. More often than not, they are used to pull in, let out, or otherwise adjust the tension of a rope or cable. A basic design of an industrial winch has a rope or any cable of some sort wound around a barrel or drum. The drum is the part that does all the work and is powered by an electric or hydraulic motor or even steam. It rotates on a horizontal axis.

Industrial winches come in different shapes and sizes and there are several types available in the market including industrial Worm Gear Winches. Each design has its own unique intended purpose.

Types of Winches

As mentioned, there are various types of winches, each with a unique design. Each type serves a different purpose and they all have their own pros and cons.

Electrical Winch

These types of winches generate electric energy from a battery to turn the motor. They have their own battery and operate independently of the car’s battery thus not affecting the normal operations of the car. Electrical winches tend to drain the battery quickly and are therefore suited for quick, occasional, and light use. one advantage of an electric winch is that it is light and therefore very easy to install. It can also be easily transferred from one vehicle to another.

Air Winch

Also known as an air tugger or an air hoist, this type of winch is normally operated by compressed air. Because of that, they are very environmentally-friendly and can be very robust compared to other types of winches. Air winches are commonly used for lifting and suspension of materials as opposed to the dragging and pulling done by other winches. They are mostly used in the construction and marine industries as well as in oil and gas production plants.

Hand Operated Winch

Just like the name suggests, these types of winches are operated manually. They consist of a handle and barrel which act as a lever and fulcrum respectively. Since they are operated manually, they are ideal for lightweight applications that don’t require too much work.

Hydraulic Winches

These winches use fluid power. A hydraulic system and motor pump are placed between the generator set and the winch. That system is the one that does all the work. Hydraulic winches typically use less energy compared to electrical winches so they are ideal for long haul operations and moving of very heavy cargo. They are also capable of an extended duty cycle for longer pulls with consistent pulling power. These winches don’t have a problem working underwater, so they are ideal for the marine industry.

Capstan Winch

These types of winches are versatile and can be powered manually, electrically, pneumatically, or hydraulically. If it has an engine, it will power the crankshaft whose pulley is connected to a device called a dog clutch thus drawing power. They consist of one extended piece around which the rope wraps and have a vertical winch drum for horizontal pulling. With this type of winch, it is possible for the line to be released from the drum at any angle and that makes it perfect for maritime operations. There are also modern capstan winches that can achieve high line pulls and high speeds thus making the job at hand that much easier.

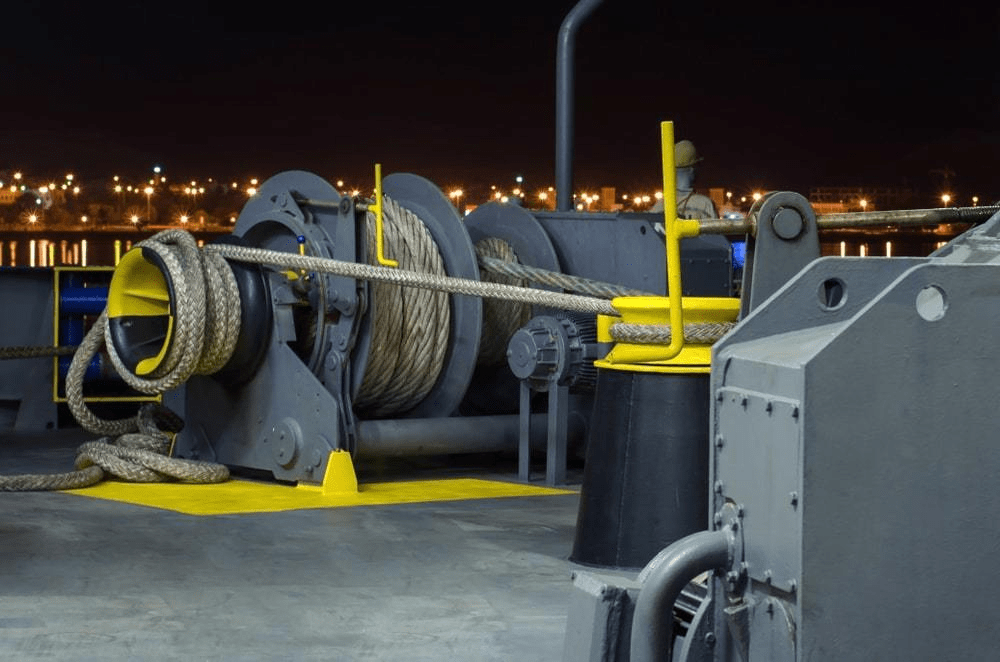

Drum Winches

These are anchoring winches that keep the rope on the drum. One of the pros of this style of winch is that you get a fast drop and fast retrieval of the load. They are also relatively easy to install and can be used with almost any type of rope and chain. As they are anchoring winches, you would almost expect them to be used on ships and that is exactly where they are mostly used.

Snubbing Winches

Unlike most winches, a snubbing winch lacks a crank handle but they have a spool positioned at a 90-degree angle. They also have tail lines which are used to reel line or tighten. Once application of force ceases, there is a lot of tension as the winch is left carrying all the weight. The pressure is then released in bits at a controlled rate using operators that are circled around the winch’s spool. Because of their design, snubbing winches are mostly used to control some ropes and the sail on small sailing boats or dinghies.

Winch Gear Types

Winches come in three different types of gear systems. The first one is called a planetary gear system. This gear system has one central gear called the sun gear which turns causing three other gears arranged around it to turn. This system is the most common out of the three and has an efficiency of about 60%

The second system is called worm gear. An industrial worm gear winch consists of two parts, a round wheel-like gear, and a bar-shaped gear. The bar-shaped gear is the one that pushes the bar-shaped one and runs on top of it. They aren’t as strong and efficient as planetary gear and have an efficiency of about 35%.

The third one, the spur gear, is made up of two wheel-shaped gears, one larger than the other. the smaller one connected to the motor and is the one that motivates the larger one. This system has a power transfer efficiency of about 75%, which is the highest among them all.

In Summary

There are a variety of winches out there and there is no particular type that stands out as the best. Each type of winch is uniquely designed to serve a particular purpose and is best suited for that purpose alone. While there are those that are multi-purpose, it is very important that you know what type of winch the task at hand requires before going to get one. you can always consult professionals like mechanics if you aren’t sure about a particular type of winch.